Article

The Emergence of Cobots in Automated Manufacturing

While the widespread deployment of robots and automation for manufacturing is the future desire for many companies, there is something to be said for the use of collaborative robots (cobots), which are robots that work in tandem with human workers. In fact, from the 1960s to the 2000s, the automotive industry used caged robots to aid in the assembly of automobiles.

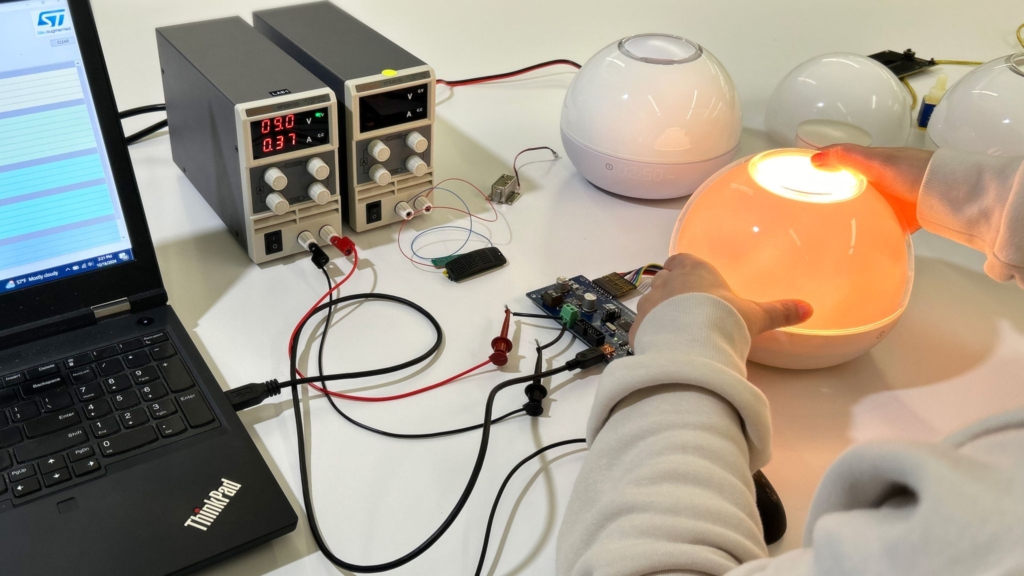

In 2008, the first uncaged robot was released into the market to work alongside humans. In more recent years, there has been considerable work to create safety standards for humans to effectively and appropriately work with cobot technology. These advances have contributed to the current climate for automation in manufacturing.

Collaborative robots allow for a less intrusive deployment of automation in manufacturing, allowing companies to mix the cognitive ability of humans with the precision and accuracy of robots.

While it sounds like the widespread deployment of robotic automation directly replacing people is the end game, it’s far from it. In nearly every case, people on the manufacturing floor are still needed in a variety of essential and valuable roles to ensure automated manufacturing runs at optimal efficiencies.

Some tasks are just not well suited or cost-effective at being automated, especially tasks that involve complex decision making, judgment, or dexterity.

It’s not practical to assume that any automated manufacturing process is capable of running without human supervision and oversight.

While “lights out” automated manufacturing floors do exist, they don’t exist completely without the oversight and presence of a crew of operators, supervisors, and technicians at the ready to intervene when needed. And, of course, humans will play a big role in designing, operating, maintaining, and testing the robots involved in automation.