Article

Medical Device Engineering and Cross-Disciplinary Collaboration

Medical device engineering: Tactical guidance and core strategic benefits

Ground-breaking healthcare services—from surgical robots to AI-powered diagnostic tools—illustrate how emerging technologies enable the rapid evolution of the medical device engineering field.

How can medical device startups and established industry players keep up as innovation accelerates?

In our experience, medical device development companies can deliver product development services at scale, meet client needs more flexibly, and accelerate their critical go-to-market initiatives by incorporating collaborative frameworks between different engineering disciplines.

This blog post explores three strategic pillars to enable more efficient medical device engineering processes:

- Cross-disciplinary methods and their potential to produce higher-quality medical devices that meet regulatory guidelines

- Cross-disciplinary collaboration and how it results in client value (from rigorous quality control to accelerated go-to-market roadmaps)

- Cross-disciplinary problem solving and its essential role in harnessing future medtech opportunities to improve standards of care and healthcare innovation

Let’s get started!

Medical device engineering and beyond: The role of interdisciplinary relationships and cross-departmental collaboration

Why not borrow from the wisdom of what works best in healthcare, independent of medical device development?

In The Case for Understanding Interdisciplinary Relationships in Health Care, authors Jasmine and Jimmie Warren discuss the tangible value of an interdisciplinary approach:

- Better communication

- More effectively structured medical facilities

- Streamlined medical treatment processes

All of these elements contribute to better outcomes for patients.

Given the patient-centric focus of the healthcare field—and leveraging insights about what works best in practice in hospitals and other care settings—the medical devices we create can (and arguably should) be guided by the same principles.

In our experience, a holistic, end-to-end medical device development approach yields healthtech products that stick the landing in the market. Thanks to collaboration between engineering specialists, clients, and end users, the final products become a logically fitting piece in the puzzle of holistic care.

But irrespective of healthcare, studies show that cross-departmental, cross-disciplinary product development leads to positive, industry-agnostic outcomes, including:

- The meaningful integration of customer perspectives

- Synchronization throughout the product development process

- Better project planning and execution

- The ability to pivot and adapt to new requirements as they arise

All of these outcomes are of immense value, especially in the intricate fields of medical device development and healthtech.

Medical device engineering specialization

At Fresh, we structure collaboration to ensure a variety of engineering disciplines work in tandem to deliver exceptional medical devices and healthtech. Depending on an organization’s internal structures and capabilities, the following overviews of different disciplines likely vary. Ask a group of Fresh employees, and they’d probably have slightly different points of view as well.

The overviews below are intended as a starting point: a general foundation for understanding what different engineers are responsible for and why cross-disciplinary collaboration is so important in the field of medical device engineering.

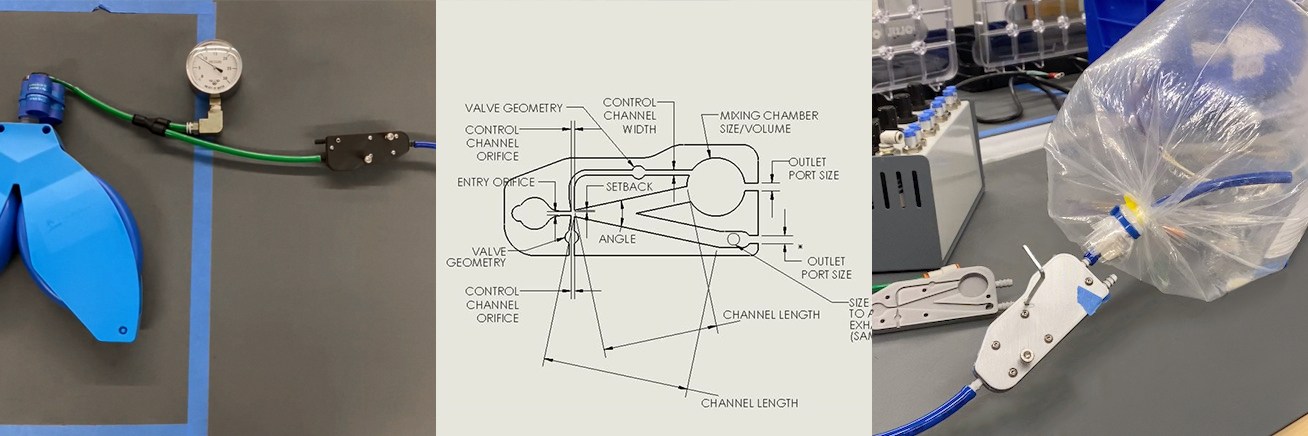

Mechanical Engineering

In medical device design and manufacturing workflows, a mechanical engineer’s key responsibilities include ensuring that a device’s structure is mechanically sound and offering expertise in optimizing the medical device manufacturing process at scale. Fresh’s mechanical engineers collaborate with specialists in other engineering disciplines to enhance the structural integrity and functionality of medical devices and other healthtech products.

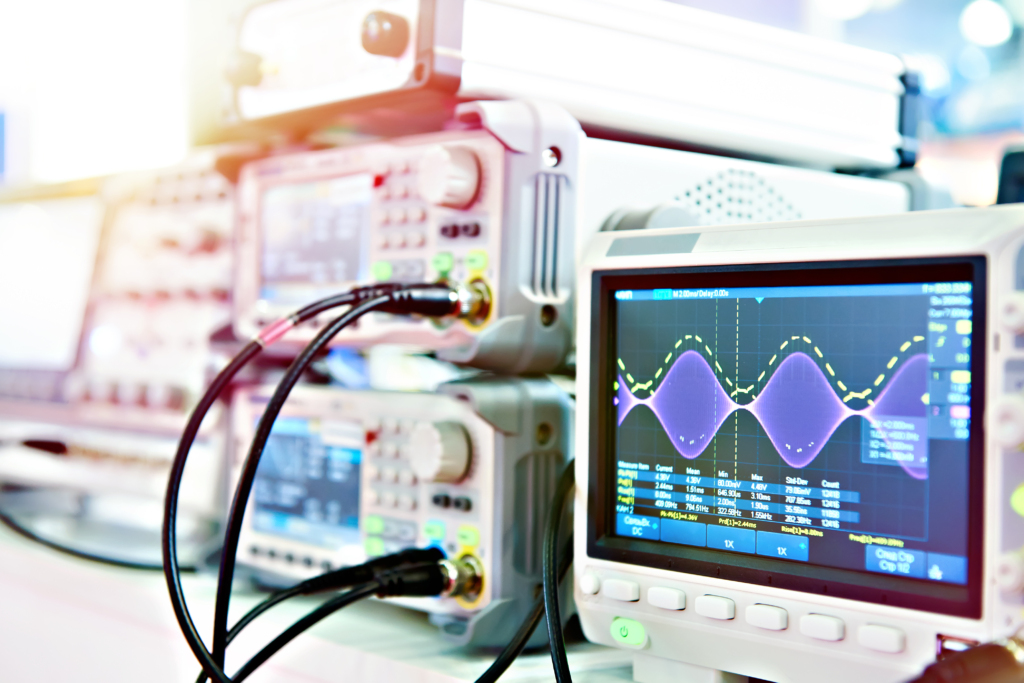

Electrical Engineering

Responsible for electrical circuitry and power systems (among many other critical system components), Fresh’s Electrical engineers design and integrate complex system features that make medical devices functional, safe, and effective for patients and healthcare providers.

RF Engineering

Radio frequency engineering (RF engineering) centers on designing and applying radio frequency technology. This technology plays a crucial role in producing wireless medical devices with the precise, diagnostically accurate quality demanded by healthcare providers.

RF engineering will continue impacting future medical technologies by enhancing the functionality and connectivity of biotech devices (bioinformatics, genomics, etc.), improving the efficacy of patient monitoring, and enabling innovative treatment that benefits from being wireless. For more information on Fresh’s approach to RF engineering, explore this LinkedIn article and its related resources.

Software Engineering

Medical device development transcends software, but software development engineers are absolutely integral in writing the code that enables medical devices to function as intended.

Software architecture is critical here. Specialists in the discipline are responsible for ensuring every element of software enhances the foundation of a high-quality medical device. A software engineer’s tasks include writing code, analyzing system performance, building cybersecurity integrations, and creating other “under-the-hood” technology that contributes to intuitive, user-friendly interfaces.

By collaborating with other disciplines—such as human factors engineers, user experience designers, and clinical experts—software developers contribute to astreamlined medical device software development process that yields functional products with powerful user experience.

For companies that need surge support or assistance with other aspects of medical software development, our post on choosing a partner provides practical guidance and insights.

Industrial Engineering & Industrial Design

In medical device development, industrial engineers focus on “production,” rather than “product.” They are responsible for:

- Building production systems that augment the capabilities of human workers with automated machines, materials, and energy sources

- Optimizing production for efficiency, cost-effectiveness, and scalability

- Ensuring systems for manufacturing medical devices and other healthtech products deliver the level of quality needed to meet regulatory specifications

- Collaborating with other engineers to continuously streamline production and mitigate manufacturing risks

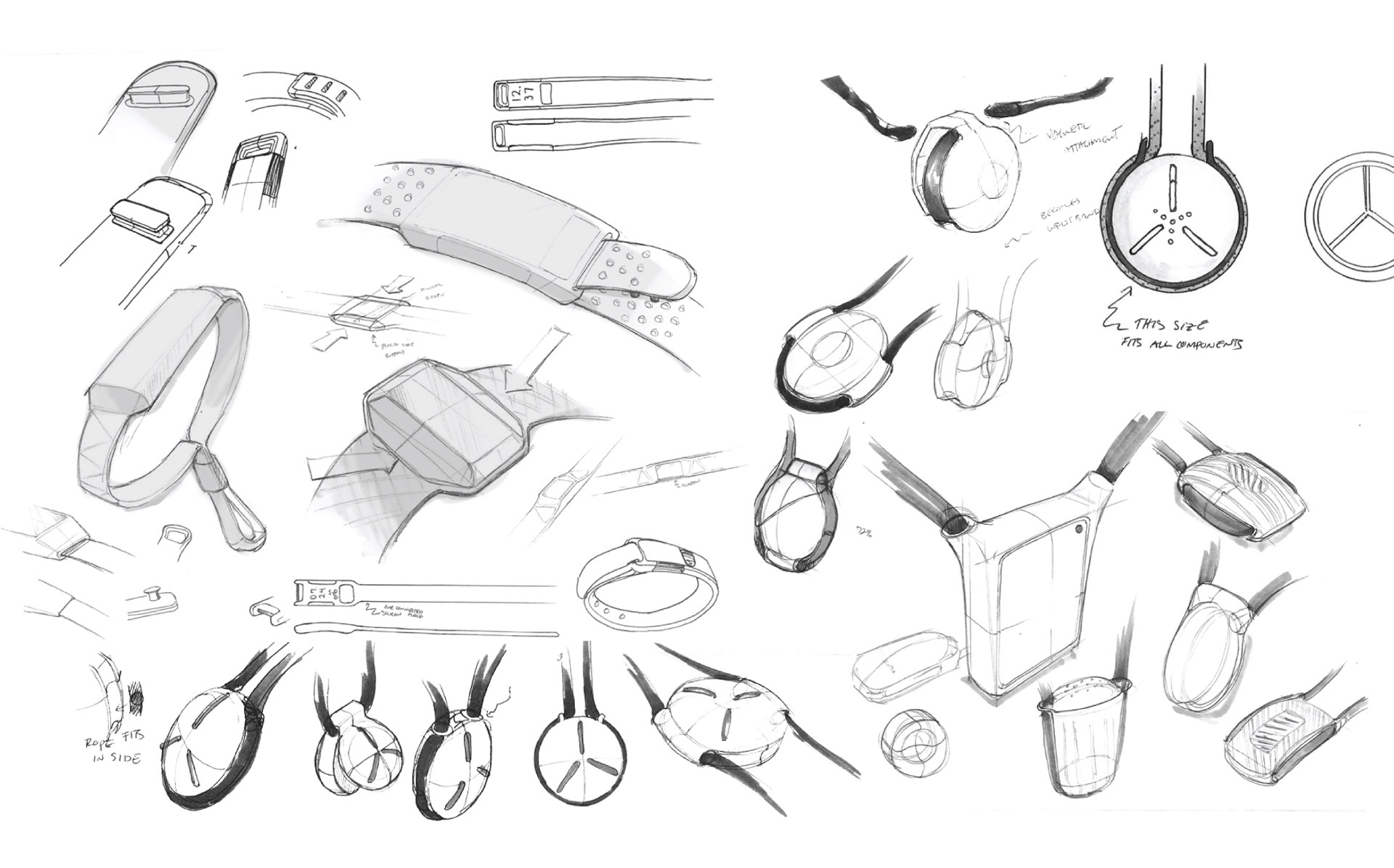

Industrial designers play a unique (albeit related) role, focusing on “product” rather than “production.” An industrial designer’s responsibilities include:

- Optimizing engineering designs to meet user needs and best-in-class ergonomic standards

- Focusing on aesthetics, the user interface, and the holistic user experience of medical devices

- Working closely with engineers to balance functionality and design

- Incorporating feedback from users to continually usability and optimization

Industrial engineers and industrial designers play critical roles in enhancing the usability, safety, and market potential of medical devices by occupying distinct yet complementary roles.

Robotics Engineering

Fresh’s robotics engineers work with engineers from other disciplines to ensure medical robots (or other automated medical devices) operate reliably. Ensuring that this happens in complex environments, where humans and machines must work in tandem, is an even bigger challenge. Cross-disciplinary collaboration enables team members to meet the challenge with confidence.

Firmware Engineering

Firmware (a type of embedded software) plays a critical intermediary role between hardware and software. Specifically related to the medical device space, firmware engineers create and manage embedded software that ensures that the hardware components of a medical device function as intended. As you might expect, firmware engineers thus play a vital intermediary role between hardware and software teams.

Two key advantages of cross-disciplinary medical device engineering teams

Comprehensive teams enable sustained, consistent innovation

At Fresh, harmony between teams is a central ingredient for innovation. In Your Guide to Workplace and Team Dynamics, we provide an in-depth review of personality tests and the types of insights they illuminate about people, the way they work, and how they collaborate with others. In our experience, we’ve found that the chemistry between people (and their personalities) is one of the great sources of value for our clients and partners and that mixing the right ingredients is possible with forethought and planning.

Not only do team members from different engineering backgrounds offer unique ways of looking at a challenge, but they also bring diverse points of view and perspectives. This ties back to some of our company’s guiding values: seeking diverse perspectives, framing problems carefully, and embracing productive friction, among others.

Ultimately, striking a powerful balance between talented people, established processes, and empowering technology leads to sustainable innovation. This is especially important in the medical device development field, where expertise from so many disciplines is required, and the complex regulatory landscape necessitates alignment.

Knowledge integration leads to more effective problem-solving

Combining diverse expertise allows a larger team to efficiently address every element of a challenge and produce innovative solutions that carry lasting impact. A mix of perspectives also fosters creativity, which can lead to unexpected breakthroughs that would be less likely with a single-discipline team.

Without expertise in mechanical, electrical, programmatic, and ergonomic factors, delivering high-quality healthtech solutions wouldn’t be possible. Not every project needs full end-to-end support—for some projects, anything beyond firmware or electrical engineering augmentation isn’t necessary. However, with the option to build robust teams that share knowledge and collaborate, every element of medical device design can be considered, accounted for, and documented, depending on the client’s needs.

Two factors for achieving accelerated development and market readiness

As stated in this article’s introduction, one of the most significant client benefits that results from cross-disciplinary collaboration is acceleration to market. With more people and more disciplines working in tandem, it stands to reason that efficiency could actually decrease. However, we’ve found that efficiency is significantly increased with seamless partnership, problem-solving, and knowledge integration for the reasons discussed below.

Streamline robust processes

Given the challenges faced by innovators in the healthcare industry—from regulatory requirement adherence to clinical trial completion—reducing time-to-market however possible is vital. Cross-disciplinary teams, when strategically and intentionally structured, can drastically streamline the medical device development process. By integrating different fields of expertise from the outset, teams can avoid the pitfalls of piecemeal product development, expediting product completion with thoroughness and organization from the outset.

Build scaffolded support systems to enable speed and rigor

In-house collaboration across the various phases of medical device development is highly beneficial. Even if a project focuses primarily on mechanical engineering and industrial design, having access to a software engineer or an RF engineer allows teams to navigate roadblocks efficiently. Teams that work together closely (even if the aforementioned software or RF engineer isn’t a formal part of the team) bring products to the healthcare market faster.

Two challenges to anticipate and solutions

Cross-disciplinary communication barriers

The challenge: Different perspectives on a challenge can lead to misunderstanding and misalignment. This isn’t something medical device developers can afford, given existing challenges related to regulatory compliance and other field-specific product development obstacles.

A potential solution: Agreed-upon processes can bypass communication barriers by leveraging pre-existing systems that enable faster decision making and conflict resolution. Improving communication and collaboration among team members is crucial.

Methodological differences & distinct engineering perspectives

The challenge: Methodological differences between disciplines can also pose challenges. Each field has its approach and priorities, which can result in conflicts if not managed properly. See the note at the beginning of this post—the definitions of the disciplines would likely catch the eye of someone who sees things differently based on prior experience, personal outlook, and professional interests.

A solution: Well-organized teams, equipped with guiding values and agreed-upon principles of collaboration, can overcome minor differences and move faster toward positive client outcomes. Team-building activities and training programs can foster a collaborative environment. These initiatives help team members appreciate each other’s strengths and work together more effectively.

Future medtech trends and opportunities for cross-disciplinary medical device engineering

AI and machine learning

Emerging technologies like AI and machine learning enable intelligent data analysis, predictive medical diagnostics, and personalized treatment plans. These advancements can potentially enhance device functionalities, improve patient outcomes, and drive further innovation.

Cross-disciplinary human-factors engineering, encompassing a range of the disciplines mentioned previously, is valuable for delivering on the full potential of AI and ML.

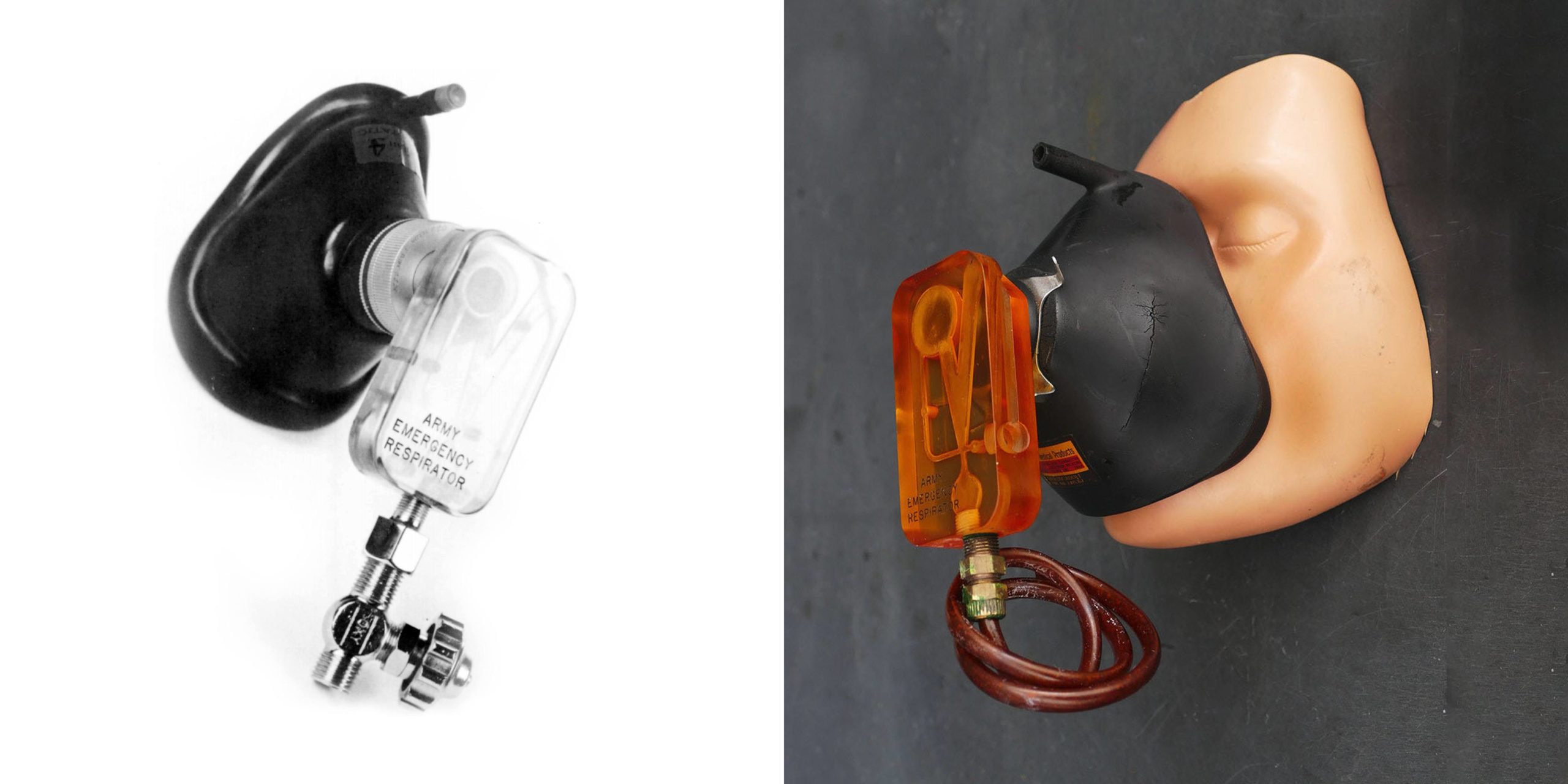

Implantable medical devices

Implantable technologies can be placed in (or on) the human body to monitor and treat a range of health conditions. Examples of implantable medical devices include cardiac pacemakers, defibrillators, stents, valves, and electrical leads, and batteries.

As AI and ML continue to revolutionize predictive analytics, personalized treatment, and real-time monitoring, implantable devices will become more effective in offering diagnostics and intervention at the individual patient level. But meaningfully merging these technologies will necessitate multi-disciplinary engineering.

Internet of Things (IoT) integration

Internet of Things (IoT) integration involves the seamless interconnection of medical devices. This connectivity enables continuous data exchange and remote monitoring. Enabled via RF engineering and related practices, IoT integration can drive future medical technology trends and opportunities in medical device engineering via real-time health tracking and personalized patient care.

From industrial design to mechanical and electrical engineering, IoT-enhanced medical devices require multidisciplinary collaboration.

Wearable devices

Wearable devices leverage sensors to continuously monitor various health metrics, such as heart rate, activity levels, and sleep patterns. Pertaining specifically to medical device development, wearables provide real-time health data, proactive disease management solutions, and promote patient ownership over personal health and wellness.

In order for wearable devices to continue advancing in sophistication, multidisciplinary engineering will play a key role.

Telemedicine applications

Telemedicine applications utilize digital communication technologies to deliver healthcare services remotely, bridging physical and geographical gaps between patients and healthcare providers. With the integration of advanced medical devices, telemedicine will further enhance healthcare accessibility and revolutionize how care is delivered, especially in underserved areas. Solutions that enable transformative data telemetry for various use cases require engineers from various disciplines working together to solve key challenges.

Nanotechnology in medical devices

Nanotechnology in medical devices involves manipulating atomic or molecular-scale materials to develop targeted drug delivery, improved diagnostic tools, minimally invasive surgical instruments, and numerous other innovations.

In medical device engineering, nanotechnology and other biomedical tools can drive future medical technology trends and opportunities. Integrating nanomaterials into medical devices will lead to groundbreaking advancements in disease treatment, early detection, and personalized biomedical healthcare solutions.

Biotechnology in medical devices

Biotechnology—or biotech—leverages biological systems and “living organisms” to develop innovative biomedical devices, biopharmaceutical therapies, and more. Biomedical engineering has the potential to drive future medical technology trends and opportunities by enabling the creation of advanced diagnostic tools (via biosensors), medicine applications, and targeted drug delivery systems. As biotechnology continues to evolve—augmented by cutting edge pharmaceutical research—it promises to revolutionize healthcare with more groundbreaking solutions that enhance patient care and treatment outcomes.

Robotics and automation

Robotics in healthcare enables increasingly sophisticated, minimally invasive surgeries, improved diagnostics, and other forms of automated patient care. Reduced human error will continue to be a key benefit, along with laying the foundation for additional automated solutions for complex medical challenges.

Cybersecurity in medical devices

Cybersecurity in medical devices is critical to safeguarding sensitive patient data and ensuring the secure operation of medical technologies. While it might seem most pertinent to software engineering, true advancement of cybersecurity technology (especially with regard to interconnected medical devices) will require a cross-disciplinary engineering approach.

3D printing for medical devices

3D printing for medical devices enables rapid prototyping, customizable design, and accelerated innovation. 3D printing technology enables teams to create complex, patient-specific devices as well. As 3D printing continues to evolve, input from multiple engineering fields will be imperative for end-user acceptance and market viability.

Automated manufacturing

Automated manufacturing in medical device engineering streamlines the production process. As automated manufacturing technologies continue to advance, scalable and cost-effective production of sophisticated medical devices will be well-within reach for more organizations. Enhanced manufacturing precision and production efficiency—with drastically reduced human error—are also key benefits.

Regulatory compliance strategies for medical device engineering

Regulatory compliance strategies are critical to ensure patient safety and help organizations enter their market with confidence. The most common set of regulatory compliance standards that medical device companies must meet are FDA regulations. FDA regulations provide comprehensive standards for medical product development through the entire design and manufacturing process.

A critical component of FDA regulations involves rigorous quality control processes, ensuring that every medical device meets industry requirements and functions correctly. Clinical trials, guided by FDA regulations, provide robust data on the safety and efficacy of medical devices. An effective regulatory compliance strategy integrates patient safety into every stage of medical product development. Detailed protocols for clinical trials align with FDA regulations to safeguard trial participants and future patients who will use the device.

Meeting FDA regulations and other industry standards requires an interdisciplinary approach. Engineers, program managers, and other project members must work closely to ensure rigorous quality control. Beyond achieving the end goal of market acceptance, cross-disciplinary collaboration enables greater speed to market and greater levels of trust within the healthcare community.

The future of medical device engineering is multidisciplinary

Cross-disciplinary expertise and accelerated development significantly benefit medical devices and health tech innovation. By integrating diverse fields, teams can enhance innovation, streamline processes, and bring groundbreaking products to market faster.

With practical project experience spanning various aspects of the healthcare industry, our team understands the importance of incorporating cross-disciplinary approaches in projects. Embracing this collaborative mindset can lead to the creation of medical devices that transform healthcare and improve patient safety and outcomes.

If you have a medical device or healthtech project—or, if you simply want to learn more about our process and approach—let’s connect.