Article

Why Custom Robots? Strengths, Applications, and Expected ROI

Custom robots are specifically designed, engineered, and built to meet unique requirements, tasks, or operational environments that commonly available robots cannot address effectively. These customized robotic systems are tailored to achieve optimal performance in specialized applications, offering flexibility in design, functionality, and integration based on the specific needs of the user or industry.

Robots and other automated solutions are the key to the expansion of modern industries, from agriculture to logistics, warehousing, construction, and transportation. The global average age continues to increase as population growth slows—it is predicted that the over-80 group is going to triple in size globally by 2050. This confluence of societal factors points to the need to think proactively about adopting automated workflows to deal with challenges related to hiring, retention, and productivity.

In this post, we’ll cover:

- Why custom robots matter

- The limitations of standard robot solutions

- The unique strengths of custom automation

- Industry-specific applications of custom robots

- Emerging technology likely to impact custom robot development

- Expected ROI for companies that invest in custom robot solutions

The robot industry will continue to expand into new applications

New applications and use cases that meet any of the following criteria will likely require a custom robot solution:

When a typical off-the-shelf robot can not be used, this includes:

- Applications with tight space constraints

- Applications where the weight needs to be minimized

- Applications where control needs to be maintained over the robot design

- Applications where industrial design intent prevents the use of an OTS robot design

- Any robot product where manufacturing volumes are high. In most high-volume applications it is cheaper to own the design rather than to integrate. In addition, owning the design means that the product can be refined over time and is not significantly dependent on an uncontrolled source.

Keep in mind that a custom robot will have different qualities and features depending on the industry, application, and use case. Refer to terminology in ISO 8373:2021 for more details about how industrial robots, service robots, and medical robots differ.

What are the strengths of standard robots? How do they compare to custom robots?

The number of available robot solutions has continued to increase, but the most commonly available are Fixed Robots and Mobile Robots. For most use cases, fixed robots and other standard robot solutions are sufficient and exceptionally good at delivering the value they’re built to deliver.

Fixed robots include articulated robots (typically 6 DoF, sometimes collaborative), SCARA, Cartesian/Gantry, and Parallel/Delta. Mobile robots include two primary types referred to as Autonomous Mobile Robot (AMR) and Autonomous Guided Vehicle (AGV). Mobile robots are available in standard form factors which are utilized across automated manufacturing and logistics/fulfillment services in large volumes.

Integrating off-the-shelf robot solutions is substantially cheaper than designing from scratch, but there are pitfalls. Relying on a platform from another supplier can be disastrous because your fate is tied to their fate. For example, it is not uncommon for suppliers to become saturated with demand from other larger customers. In addition, suppliers can make revisions to their hardware that cause problems in your product. For this reason, in most cases, robot integration should only be used in low-volume applications.

Commonly available solutions are often insufficient for specialized environments and/or lack the flexibility to perform unique tasks. For example, industrial solutions are often not suitable for medical environments because of requirements for maintaining clean, sterile hospital environments.

Using commonly available solutions can also introduce inefficiencies or performance compromises. For example, an available robot arm is designed for dynamic applications with a higher duty cycle than what is required for certain use cases, and for that reason is much larger and heavier, and more expensive than what the robotic solution needs to be.

The Pixster Glambot is an example of what a simplified solution can be.

What are the advantages of custom robots?

Custom Robots are becoming a more popular and cost-effective solution. Not only is robotic automation an effective solution for challenges like labor shortages, but it’s also becoming easier to create tailored solutions designed for specific tasks and optimized for unique environments (e.g., underwater, hazardous areas, space exploration).

Custom robot hardware and software continue to improve as well. For hardware, the availability of frameless motors, gearbox solutions, servo drives, and other components continues to increase. This steady increase provides options for design engineers and has created a more healthy and competitive environment.

Software has also made large strides. ROS 2 has become a more dependable platform for the development of robot systems. More suppliers provide SDKs and drivers that are ROS 2 compatible which eliminates the need for custom drivers to be created. OS-compatible platforms for rapid robot development like Nvidia’s Omniverse and Autoware continue to improve. Other competing low-cost platforms have continued to improve including Microsoft Robotics Developer Studio (MRDS) and YARP.

For products such as service robots, custom robot product teams want to create a product that is integrated, unique, and stands out in the marketplace. During the product development process, the specific requirements are defined and the custom robot can be designed for the specific environment, duty cycle, payload, etc. By designing to the environment the material cost can be optimized to fit that specific application. In high volumes, this approach will net a long-term ROI as compared to integration.

Additional benefits of owning the design allow for easier revisions and improvements to the product. Easier expandability, add-ons, and accessories are other possible sources of revenue generation and in some cases make integrating emerging technologies possible.

Applications of custom robots: Industry-specific examples

Space exploration

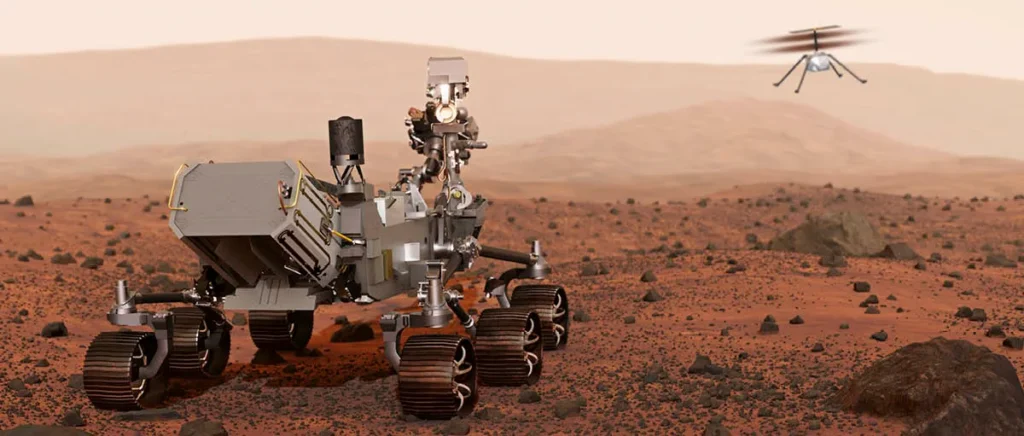

Custom robots play a vital role in space exploration and operations, addressing unique challenges such as extreme environments, limited human access, and the need for precision.

Robots used for space applications include Mars and Lunar Rovers ( e.g., Perseverance, Curiosity, Yutu-2). Customized robots are also used to help crews aboard the ISS. Past projects such as NASA’s Restore-L and their future iterations will kickstart the satellite servicing industry and expand the immense potential of the space economy.

Other custom robot applications in the works include space mining, construction in space, and further space exploration.

Construction

Custom construction robots continue to be a major focus of robotic automation. In 2022, the global construction robots market was valued at over 168 million dollars. By 2032, the market is expected to reach a valuation of 774 million dollars.

The use cases and applications of construction robots are extensive. Built Robotics focuses on autonomous bulldozers, excavators, and compact loaders and has raised a total of $112 million. Other startups include Dusty Robotics, SAM (Semi-Automated Mason), and Apis Cor.

Fresh engineers have taken part in advancing automation capabilities in the construction industry as well. As United Rentals set out to automate their construction vehicle fleets, our team played a critical role in building an autonomous Club Car, an autonomous compact track loader, autonomous forklifts, and mission control software to enable human operators to manage autonomous vehicle fleets safely and reliably.

Medical Robots

The global medical robotics market was valued at over 11 billion dollars in 2022; by 2032, that figure is expected to grow to over 52 billion. Notable medical robot startups include:

- The Capstan Robotic Cardiac Platform for heart valve replacement

- Mendaera’s robotic platform is being developed for foundational, everyday procedures.

- Noah Medical’s Galaxy System is designed to eliminate lesions in the lungs.

- Opentrons specializes in laboratory automation, Opentrons has achieved a valuation of $1.8 billion, with investments from notable figures like Bill Gates and Vinod Khosla.

Agricultural Robots

The agricultural robot market is projected to grow from USD 6.72 billion in 2023 to USD 17.29 billion by 2030. Notable agricultural robot startups include:

- Aigen develops autonomous, solar-powered robots designed for various farming tasks, including weeding and soil monitoring

- Carbon Robotics has developed the LaserWeeder, an AI-driven robot that uses computer vision to distinguish between crops and weeds

- Verdant Robotics provides advanced robotic solutions for precision agriculture, focusing on tasks such as weeding, planting, and crop management

- Tortuga AgTech operates the world’s largest commercial harvesting robot fleet, with 150 production robots.

Emerging technology for custom robot development

AI and ML

The emergence of AI and ML will impact custom robot development in numerous ways, but these three are worth paying attention to.

- Human-Robot Interaction (HRI): As Human-Robotic Interaction (HRI) develops, the requirement for specialized programming skills will become less important. Our collaboration with Ally Robotics, to build a smart, serviceable, lightweight robot arm alternative, is a key example. Through natural language processing (NLP) robots will continue to communicate more naturally with humans. Robots will continue to become better at recognizing and responding to voice commands, contextual cues, and human emotions.

- Predictive maintenance and Reliability: Data from robot fleets will be used to predict failures and make predictive maintenance a powerful tool. This will allow robots to be serviced or service themselves in intervals and avoid breakdowns during critical periods.

- Generative AI will lead to enhanced autonomy: Self-learning robots will continue to become better at adapting to their environment and making dynamic decisions. Generative AI applied to robotics can simulate thousands of potential scenarios to prepare robots for unexpected events or decisions in real-world applications. Swarm Robotics, as an example, draws inspiration from natural swarms such as ants and will be significantly enhanced by generative AI.

Mobile Manipulators

The combination of mobile robot platforms with robotic arms is continuing to be utilized more. Mobile platforms such as AMRs and AGVs are great for many applications but adding a robotic arm makes them useful in many applications that require both precision and mobility.

Digital Twins

Using real-world operations data to run simulations and predict outcomes digital twins are reducing the time to market for robotic systems. The digital twin allows designers to prototype robotic systems virtually which is less time-consuming. Once the physical twin is built, real-world data can be fed back into the digital twin to predict service requirements, verify performance, improve quality, and drive design improvements.

Expansion of Cobots

Cobots with larger payload capabilities continue to enter the market. In addition, cobot solutions for custom robots such as servo drives and actuators with redundant encoders and brakes continue to become more available.

Humanoid robots

Humanoid robots are being deployed to take on dull & dirty tasks but also be human companions. China has taken the lead with ambitious goals to mass-produce humanoids by 2025.

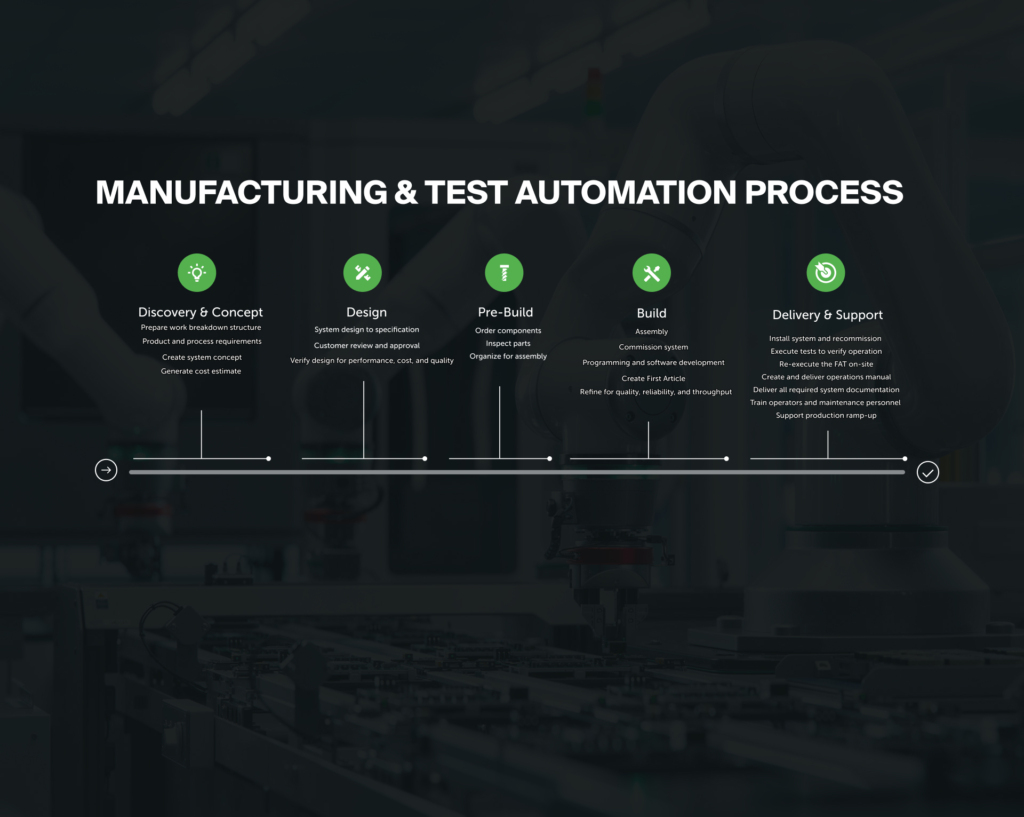

Developing custom robots and the path to value for innovative organizations

The process for the development of custom robot products has the same general phases and structure of the typical product development cycle. However, special attention should be paid to the following areas:

- ROI: Product strategy should be heavily involved early on in the discovery process to determine the correct direction for the product. Alignment on risk and cost with respect to product direction is especially important in robotics projects, especially custom projects that are more complex and resource-intensive.

- Safety: Because of the dynamic nature of robots safety is a large driver in many robotic applications. For large complex robot systems risk assessments and Failure Mode and Effects Analysis (FMEA) need to be performed regularly during the design process.

- Compliance: Because robots are typically complex products it is likely that they need to conform to several robot standards in addition to other industry standards.

- Testing: Robots are often employed in difficult environments and under dynamic conditions. For this reason, HALT testing and HASS testing are often employed during the testing of robot products to improve reliability.

- User training & support: Training users of robot systems is especially important for the product to be successful. Complex machines like robots often require considerable user training and support. Human interaction needs to be considered early on in the development process.

- Upgradeability: With advances in AI on the horizon, how the product can be upgraded needs to be kept in mind throughout the development including how firmware and UI can be updated easily while maintaining compliance with safety and certification requirements.

In conclusion, robots are complex products that need special consideration during the product development process to be successful. A successful approach involves working with a multidisciplinary team to guide the development of product strategy through production.

However, if the development process is navigated successfully the product will a feasible entry point into a rapidly growing market.