Hardware

To ensure that engineered products are successfully assembled, we deploy test automation for manufacturing reliability, configuration accuracy, and much more. Our comprehensive process applies the proper specifications, limits, process flow, and timing to ensure consistency, automated data collection, reliable operation, and optimized test throughput.

Core competencies for test automation

- Test Planning, development, execution, and reporting

- Design of Experiments (DoE) and optimization

- Development of novel tests and equipment

- Test suite development

- Test execution case oversight

- Failure analysis, pareto, and reporting

- Test planning and procedure development

- Test Suite development planning and execution

- Reliability engineering

- Performance and reliability testing

- Failure mode and effects analysis (FMEA)

- Product verification and validation

- Design verification test and engineering planning

- Acceptance criteria development

- Gauge R&R planning and execution

- Safety and compliance

- Certification management

- Design for Manufacturing

- Evaluation for manufacturability and test

- Manufacturing strategy, manufacturing partner selection, and management

- In-line test automation integration

- Manufacturing line design, bring-up, and support

- Assembly automation design and development

- Automation installation, commissioning, and support

- Tooling design, development, and vendor selection

- Remote and on-site line assistance and troubleshooting

- Service and warranty channel support

A vetted process

Optimized Timelines: We plan and develop test schedules that ensure your product is delivered on time. With our expertise in creating test systems fast, we ensure that customized test solutions can be developed and integrated into manufacturing lines, supporting your product release.

Custom and Off-the-Shelf Testing Solutions: Our Hardware Test Automation workflow brings your test plan to fruition. Whether you choose to develop a customized approach with test executive frameworks or leverage our National Instruments experience, we help you create automated testing systems efficiently.

Geographical Flexibility: Geography and scope can affect test plan implementation. We have experience deploying systems overseas, from Taiwan to Mexico, from China to Indonesia. Our scalable workflows and partnerships allow us to handle large scope and scale.

Rapid test automation development

Fresh is one of the top National Instruments Alliance Partner companies in the Pacific Northwest. Our team of LabVIEW developers includes a mix of Certified LabVIEW Developers (CLD) and Certified LabVIEW Architects (CLA).

Deep knowledge of National Instruments packages such as RealTime, FPGA, Vision, Robotics, and more, coupled with experience in multiple programming architectures, allows our LabVIEW team to develop test automation solutions rapidly, at any scale.

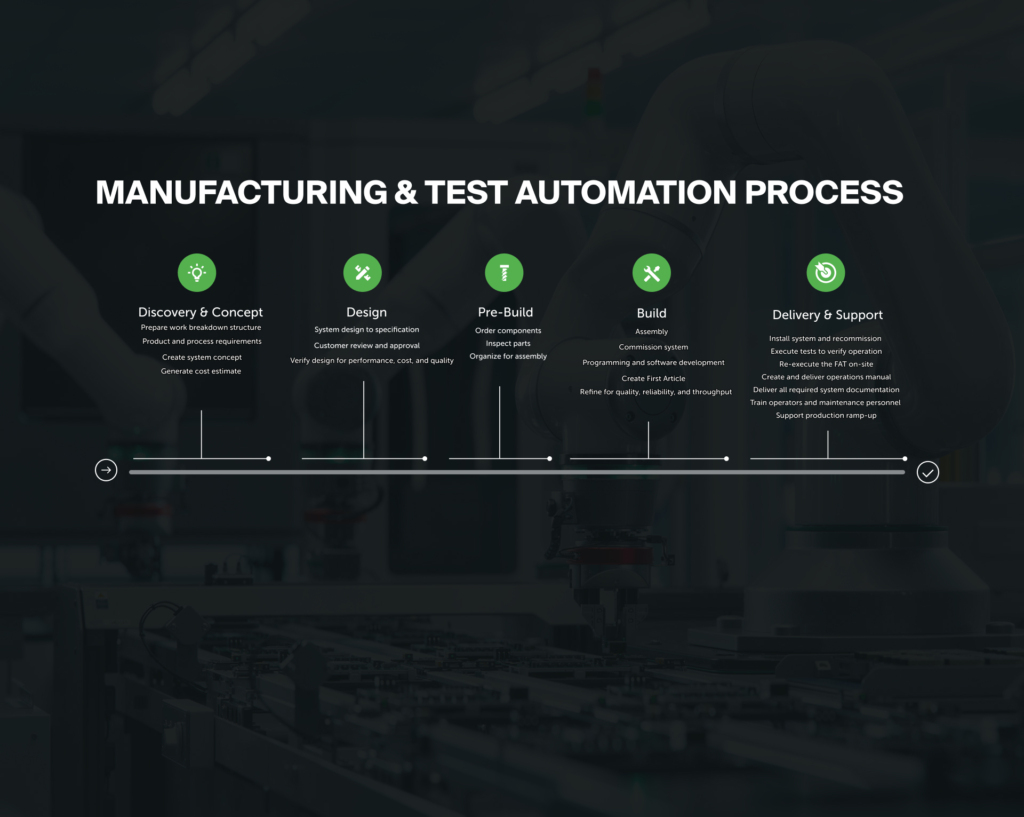

Our proven test automation process

Explore our comprehensive process for test automation for product reliability and accuracy, addressing core elements like business discovery, project planning, virtual design and physical building, and system delivery.

Related hardware capabilities

Explore our other robotics and engineering services, which allow our team to solve challenges for your organization and others, regardless of size, industry vertical, or product category.