Test Automation Systems

Precision Assembly & Calibration System

Enabling precision assembly and calibration for a consumer healthcare product

Background

An innovative healthcare company came to Fresh with the opportunity to support the manufacturing and test of a device with a novel implementation of force sensor-based buttons. Fresh engineers were enlisted to rapidly create a set of automated assembly and calibration fixtures to facilitate product development and pilot production runs. Fresh has a long history with this company, developing equipment to automate unique testing and R&D functions that often lead to high throughput equipment on the assembly line when they go to mass production.

Challenge

- Designing and building the equipment in parallel to ongoing product design.

- Identifying critical features and components to enable procurement and system integration while allowing sufficient flexibility to support anticipated design changes.

- High-precision assembly tolerances and installation pressures were required for reliable operation and calibration.

Services & Capabilities

Concurrent production line work

Our client on this project is a leader in the healthcare space, always innovating and developing new products. With ongoing R&D comes the challenge of delivering continuous value quickly and reliably, while never sacrificing quality.

To meet their ambitious go-to-market timeline, our client couldn’t wait for the product finalization before beginning the design of the manufacturing and testing processes. Part of the challenge for our team was creating a test system while firmware development, PCB design, and industrial design were ongoing.

Working closely with their team and creating a modular test program to assemble and calibrate parts of the device, Fresh was able to design and test concurrently—a huge value add for a company moving fast.

Supporting their team to accelerate product development

R&D is time-consuming. Any opportunity to increase speed is invaluable.

As with many of our engineering projects, the client hired our engineers to provide strategic consultation, backed with practical engineering experience. Their team had figured out the tech—it was our job to make it a reality and to ensure that manufacturing could begin the moment final product adjustments were complete.

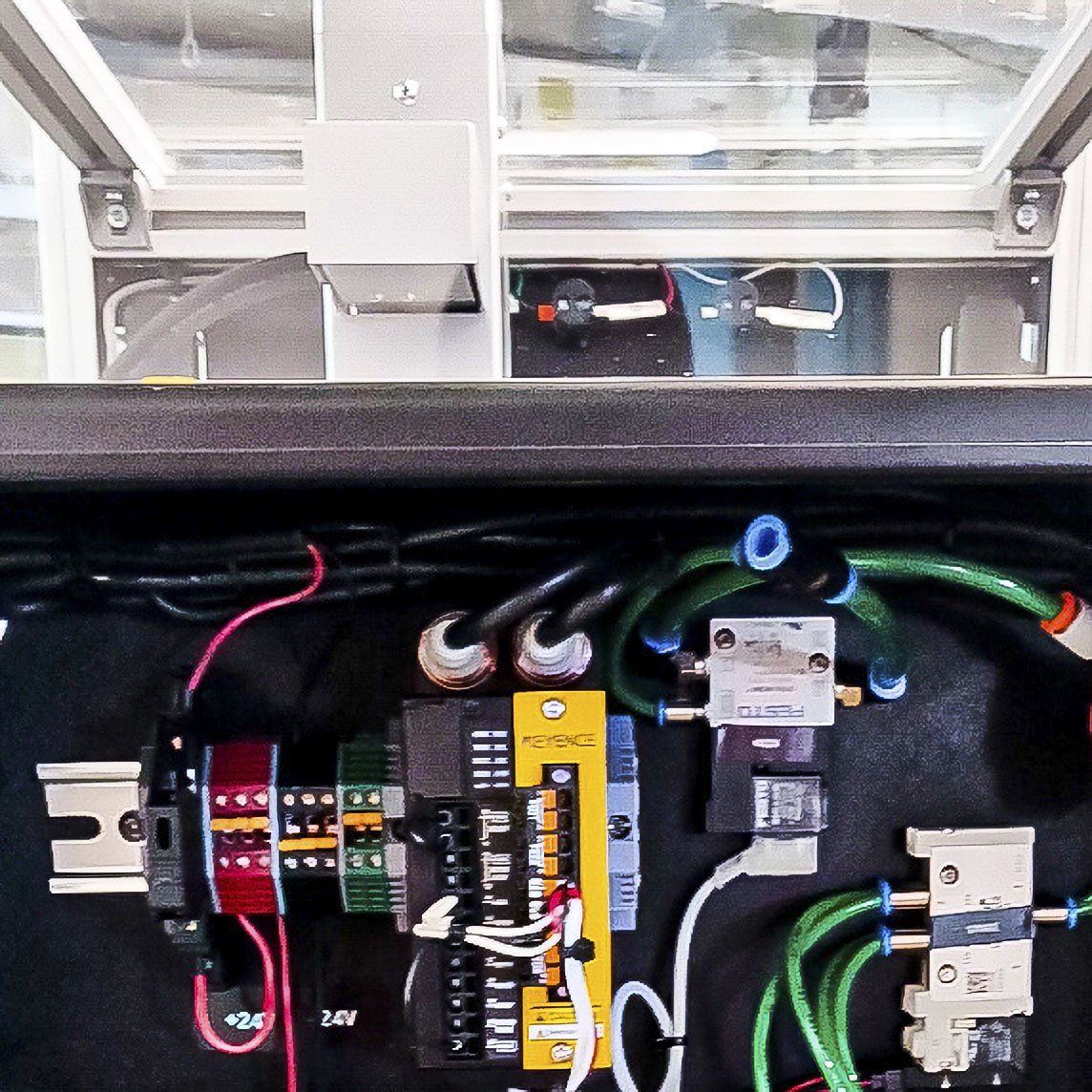

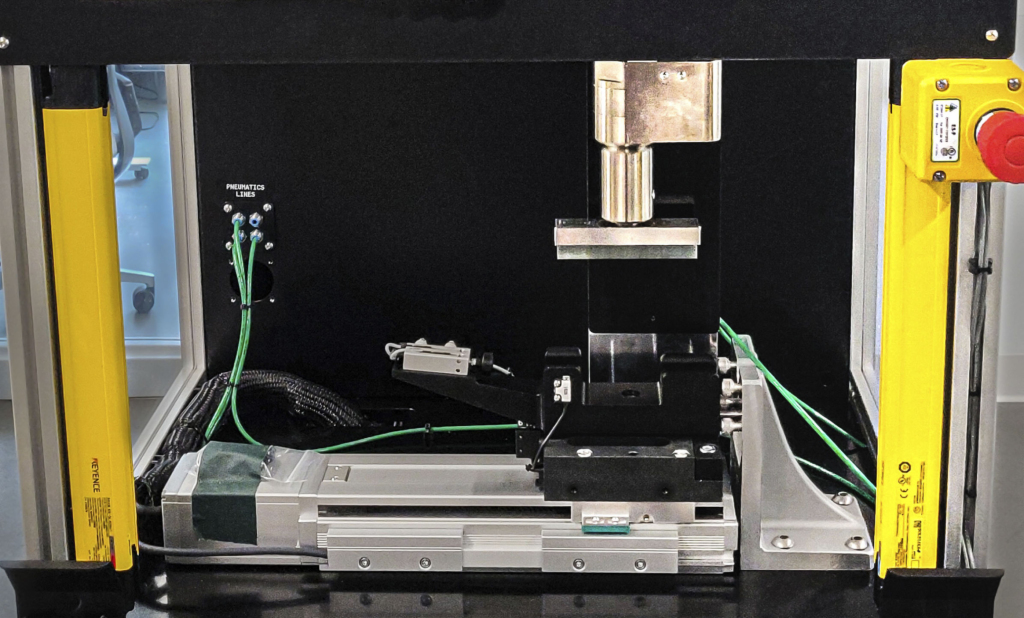

Technologies demonstrated

• Submillimeter automated placement

• Servo-controlled press (specs)

• Control lamination down to ±0.3N accuracy

• Vacuum system and Flex PCA

• Manufacturing and robotics

• Accurate placement

• Tabletop robotics

5±

±5 microns (≤ 0.005 inches) PCB installation placement accuracy

0.3N±

±0.3N (≤ 0.07lb-f) force-sensing accuracy

7s

Tack-time for process ≤7 seconds per unit